| | Videos

Bitte klicken Sie auf das Bild und das Video startet | Daten

Bitte klicken Sie auf "öffnen" um das Dokument zu lesen | | |

| | 项目建议书和可行性简要分析 Project proposal

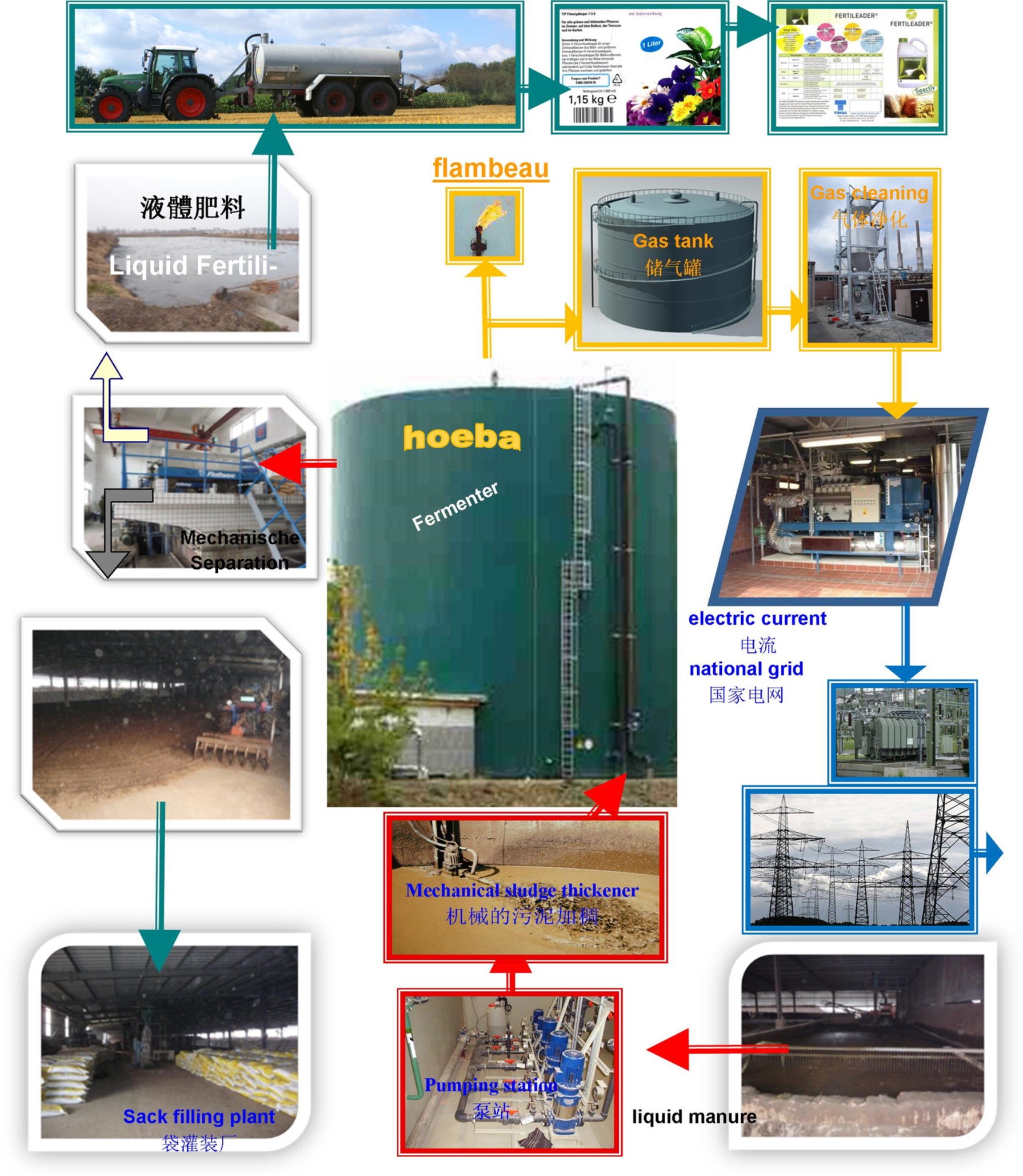

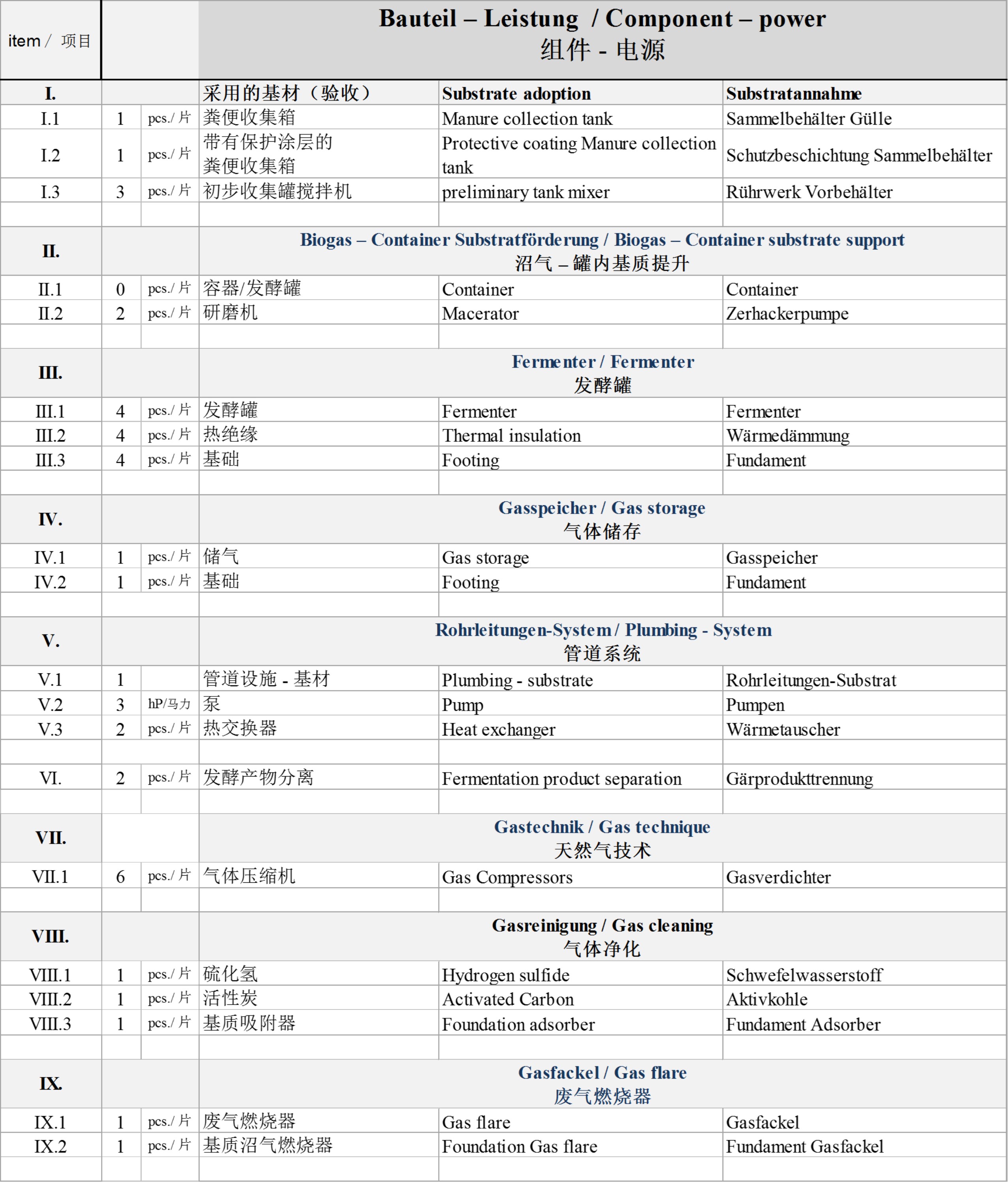

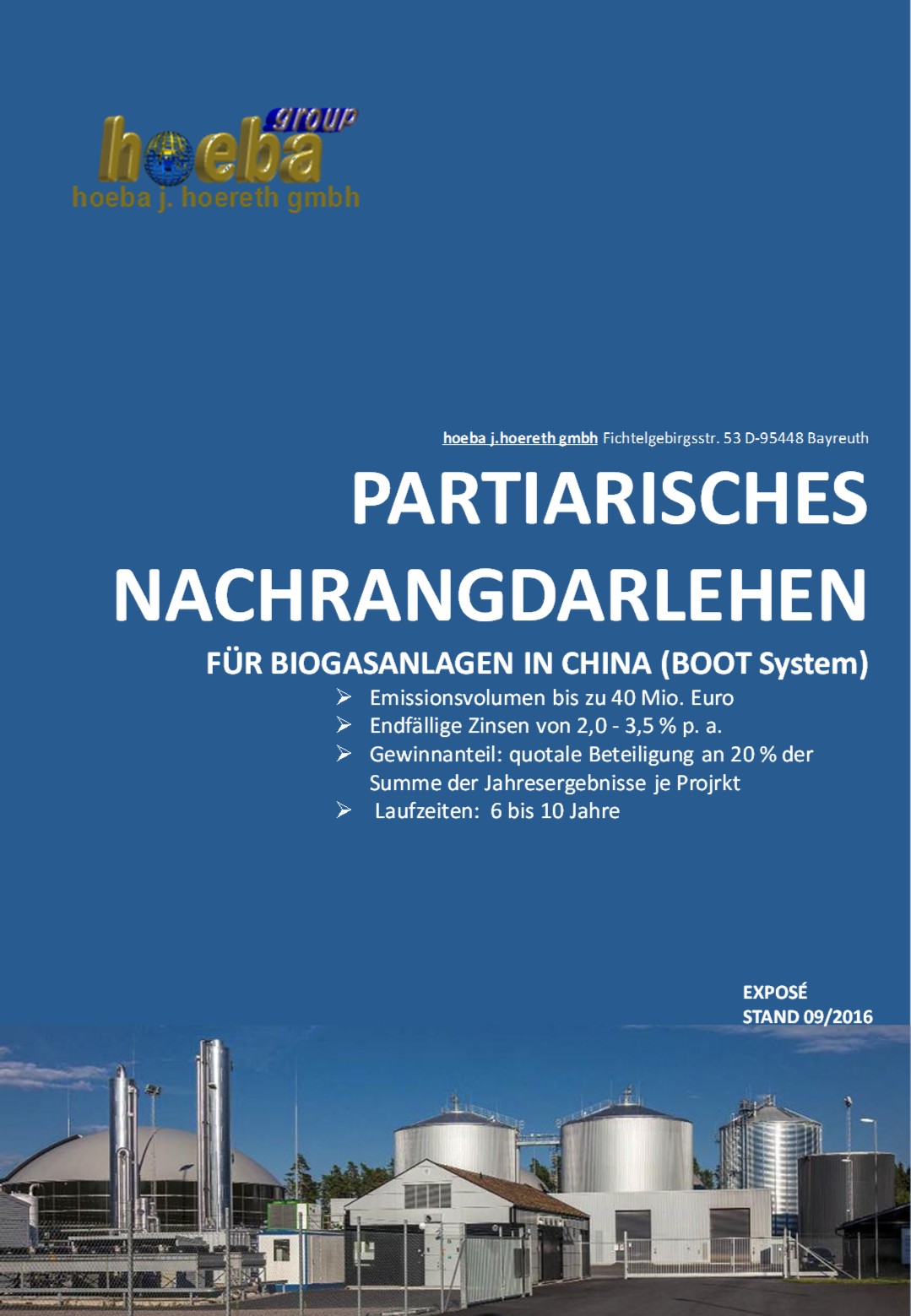

| It is us the HOEBA Group are honored to introduce our biogas plants with the best and most profitable system at the moment. | 我们赫巴(HOEBA)集团很荣幸能有机会向您介绍我们目前最先进的和有经济效益的沼气生产系统。 | We are in a position producing through our special system 365 days biogas. | 我们有能力通过我们的特殊沼气生产系统确保365天连续运营。 | The recovered energy (methane gas) we transform into electricity and heat. | 从沼气中被回收的能源(甲烷气)将被转换成电能和热能。 |

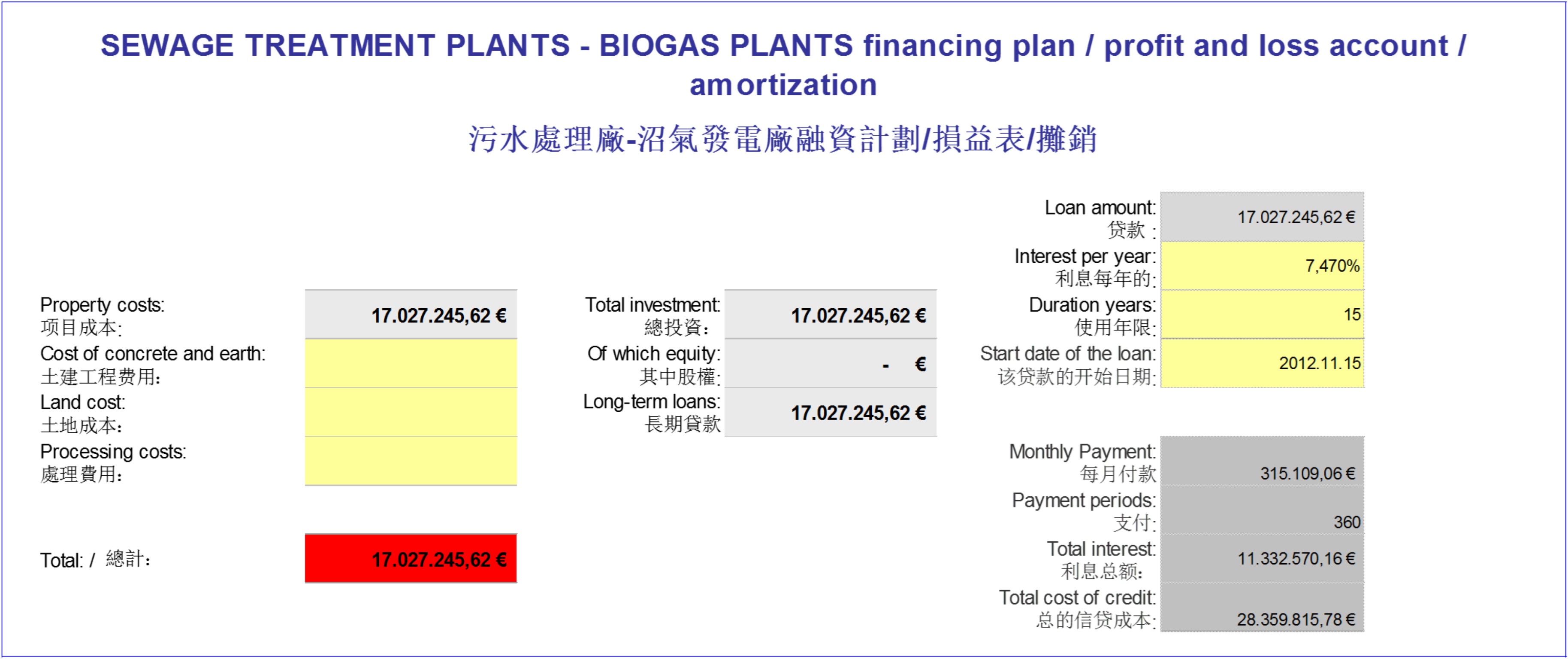

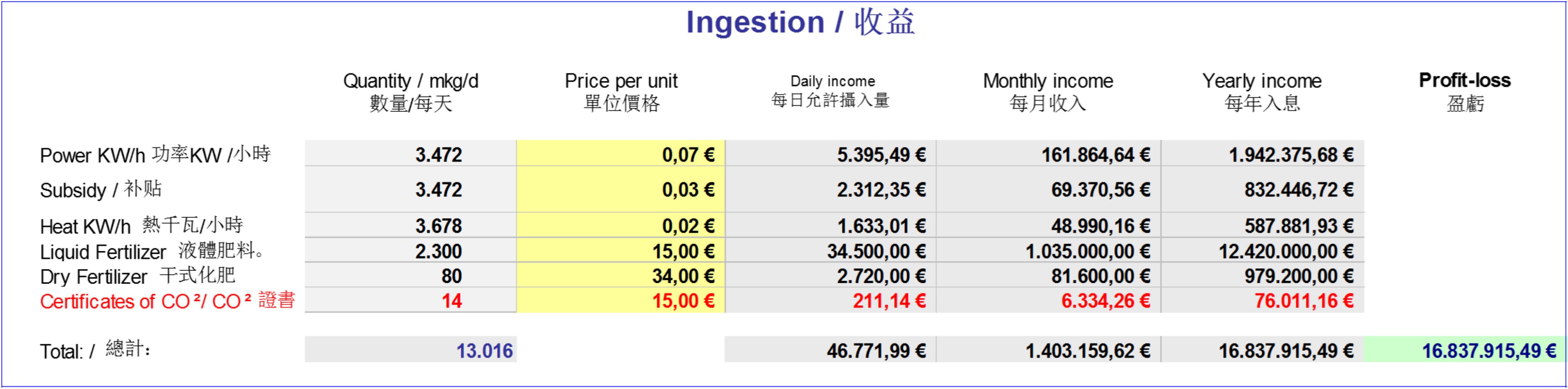

| The heat (over 400 ° C) can be used prepare hot water or to change through heat exchangers in refrigeration. | 热能(400度以上)可被用于准备热水或通过换热器转换后用于制冷。 | Full of energy yield of methane gas. | 可以使发酵原料达到最大的产气量 | In the following quotation, we present a sample of a biogas plant. | 在下面的報價中,我們提供了一個完整的沼氣廠的模式。 | From the groundbreaking to finish our offer includes everything. Planning Concrete work and earth work Machine Technology Commissioning Familiarization training for staff | 我们的报价包括從地面土建( 包括建筑材料)到交钥匙工程全部完工的一切程序: 規劃 (方案设计) 混凝土工程和土方工程 機械技術 調試( 试运转) 员工的熟悉培訓工作 | The detailed role and functioning of a biogas plant is following in detail. | 沼氣廠詳細的作用和功能的詳細說明如下: | The biogas plant will be ready for the existing methane converted into electricity. Next is dried manure in bags packaged for sale processed. Similarly, high-quality liquid fertilizer (nitrogen and phosphorus fertilizer) won that can be sold. | 沼氣廠將可以對沼气中的甲烷气体轉化成電力, 热能或天燃气,车用燃气。 其次是袋包裝干燥肥料( 沼渣)的出售。 同樣,高品質的液體肥料-沼液(氮,磷肥)可以出售。 |

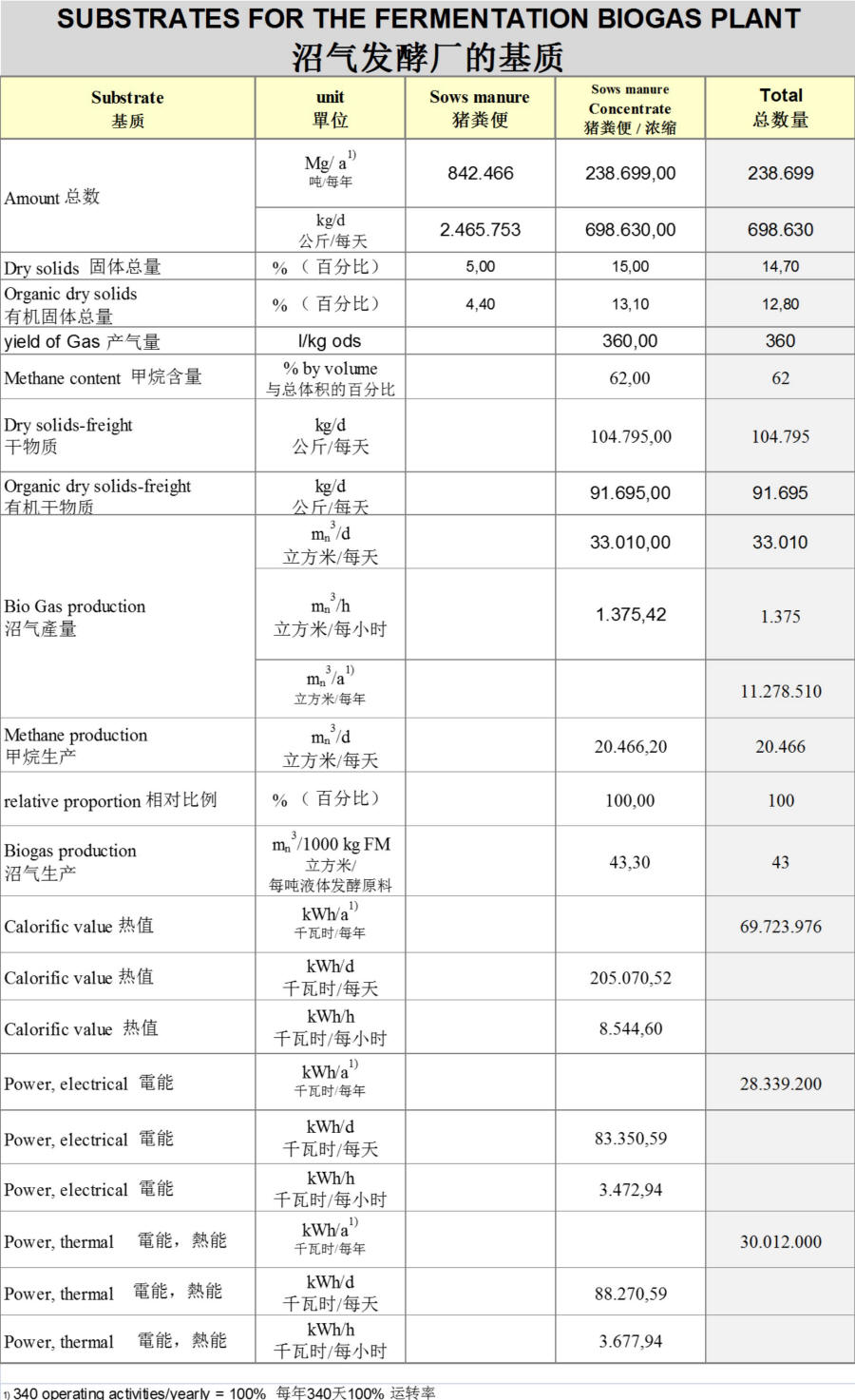

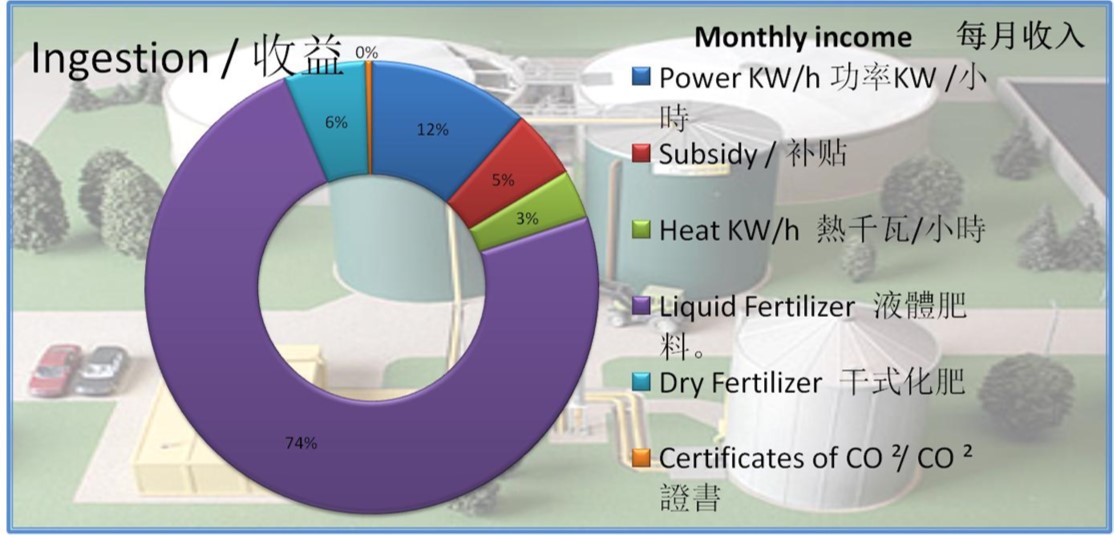

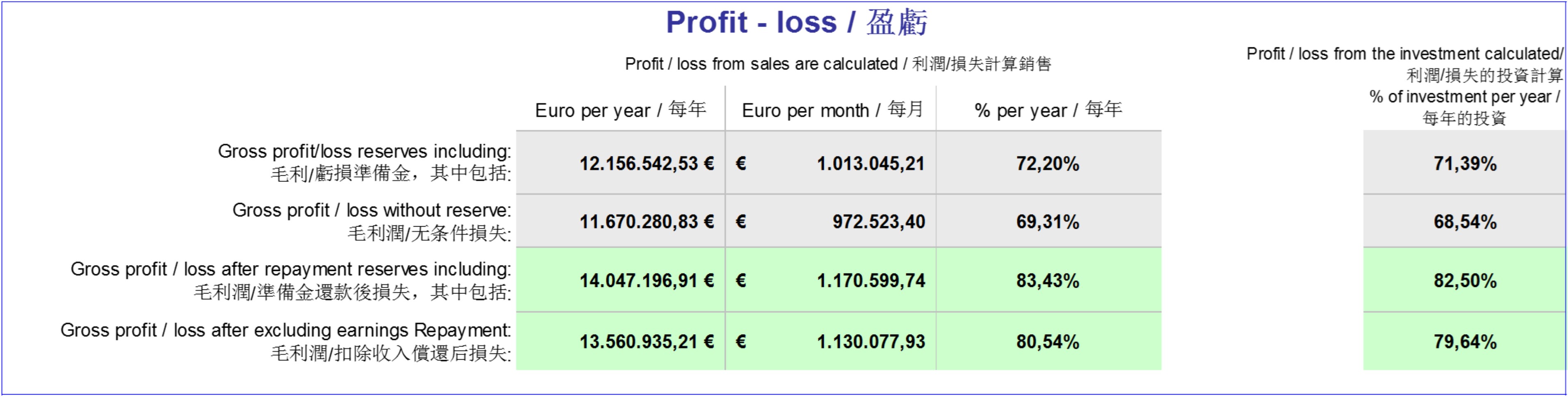

| | According to our experience we can for your documentation a Biogas production of circ mn³/a 11.223.400 | 根据我们的经验和你们提供的资料,我们可以估算出 沼气生产量大约为: mn³/a 11.223.400 | Electricity production of circa: kWh/a 28.339.200 | 如果产生的沼气全部用来发电, 可产生的电能大约为: kWh/a 28.339.200 | Heat production of circa: kWh/a 30.012.000 | 产生的热能大约为: kWh/a 30.012.000 | | | CO² Grants: This biogas project shall be implemented as CDM project according to Article 12 of the Kyoto Protocol (Clean Development Mechanism), and its associated rules of the CDM Executive Board (EB) to the United Nations Framework Convention on Climate Change (UNFCCC). | 二氧化碳 证书: 该沼氣工程将根據京都議定書(清潔發展機制)第12條规定,以及相关的聯合國氣候變化框架公約(UNFCCC)清潔發展機制(CDM)執行理事會(EB)的相關規則,作为CDM (清潔發展機制)項目實施。。 | A detailed report on the CDM procedure can be found following. | 關於清潔發展機制程序的一個詳細的報告可从下面段落找到。 |

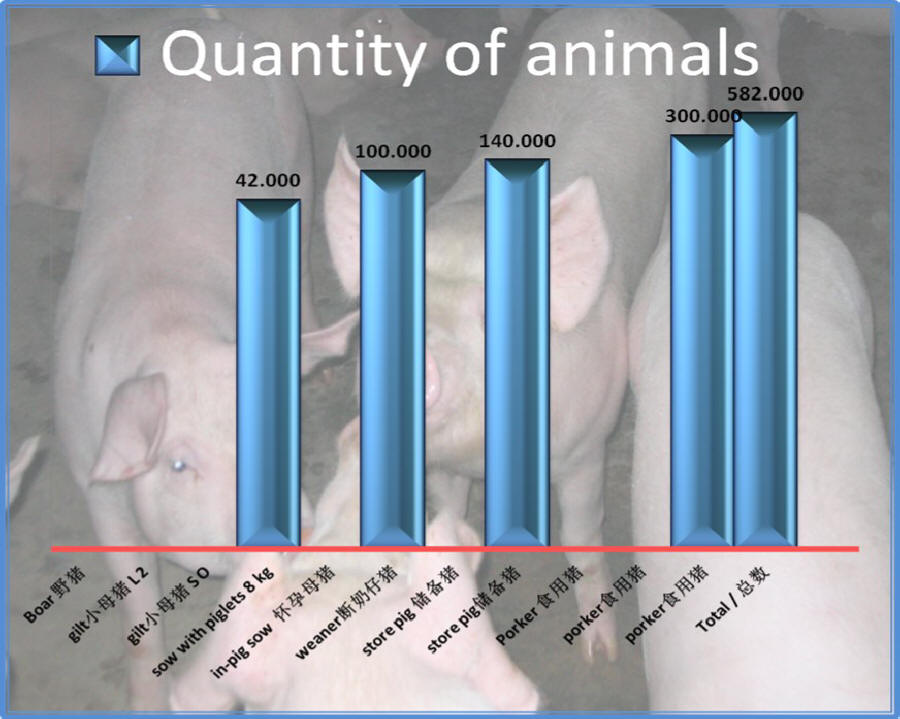

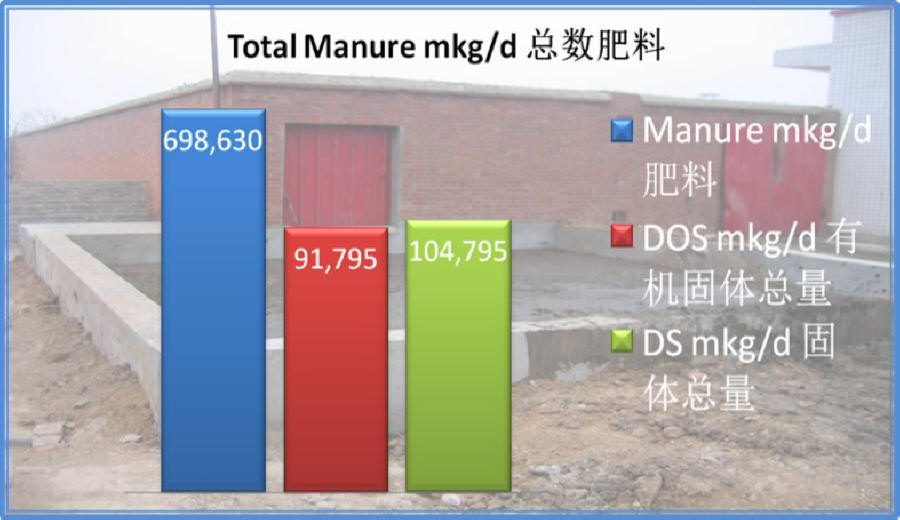

| | QUESTIONS FOR THE KIND AND QUANTITY OF LIQUID ANIMAL MANURE 有关动物液体粪便的种类和数量的问题 | | Liquid animal manure 液体动物粪便 | Quantity Piece 数量 Kg/头·天 | % drying substance 干物质 | % organic drying substance 有机干物质 | PIGS 猪 ; 640.000pcs | | | | Breed sows繁殖母猪 ; 42.400pcs | 2.8kg | 29% | 26% | Piglet小猪: 100.000pcs | 0.6kg | 26% | 22% | Runner 20 - 50 kg, 20-50公斤的猪 : 140.000pcs | 1.2kg | 28% | 24% | Pigs over > 50 kg 50公斤以上的猪: 300.000pcs | 1.8kg | 29% | 25% |

| Litter 干草(草荐) Kind of indoor livestock farming牲畜饲养场的种类 | Columns ground Piece 存栏猪数量 | Straw Piece 秸秆量 | wood shavings Piece 木刨花 | Other Stuff Piece 其他材料 | PIGS猪 | 640.000 | | | | Breed sows繁殖母猪 | 42.400 | | | | Piglet小猪 | 100.000 | | | | Runner 20 - 50 kg 20-50公斤的猪 | 140.000 | | | | Pigs over > 50 kg 50公斤以上的猪 | 300.000 | | | |

| Litter per day per animal 每头猪每天的干草(草荐) | Columns ground Water kg per animal 存栏量每头猪每天用水的公斤数 | Straw kg per animal 每头猪每天用稻草的公斤数 | wood shavings kg per animal 每头猪每天用木屑或刨花的公斤数 | Other Stuff kg per animal 每头猪每天使用的其他材料的公斤数 | PIGS猪 | | | | | Breed sows繁殖母猪 | 30 | | | | Piglet小猪 | 10 | | | | Runner 20 - 50 kg 20-50公斤的猪 | 15 | | | | Pigs over > 50 kg 50公斤以上的猪 | 20 | | | |

| | | Dung and sewage processing concept | 糞便和污水處理概念 |

|  | | |  | | |  | | |  | | |  | 1 Fermenter 2 Stair tower 3 Collection tank 4 Maschine house CHP 5 Gasholder 6 Flare 7 Road | | | | | | B. Biogas plant description and operational function | B. 沼氣工廠描述和功能介绍 | | |

|

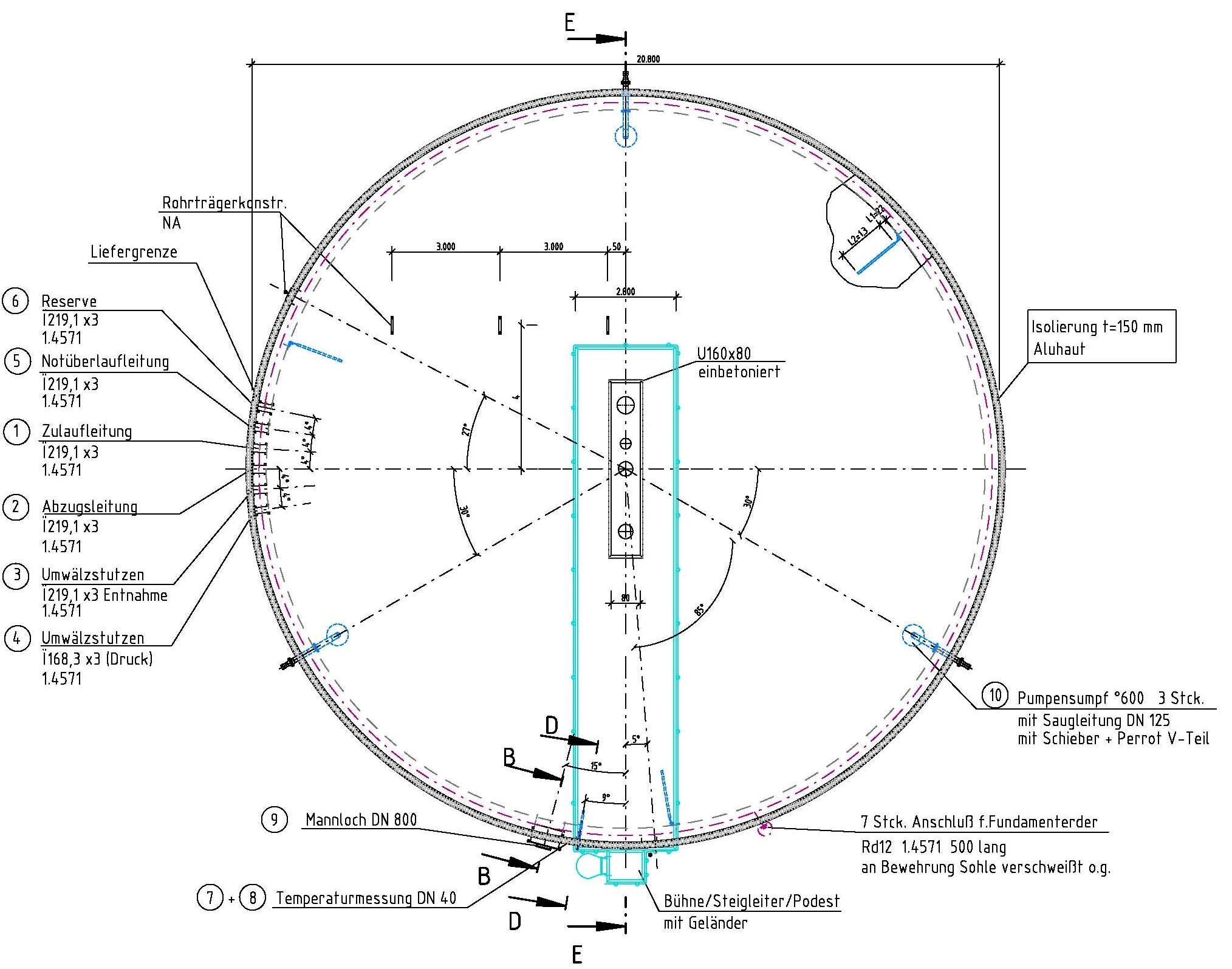

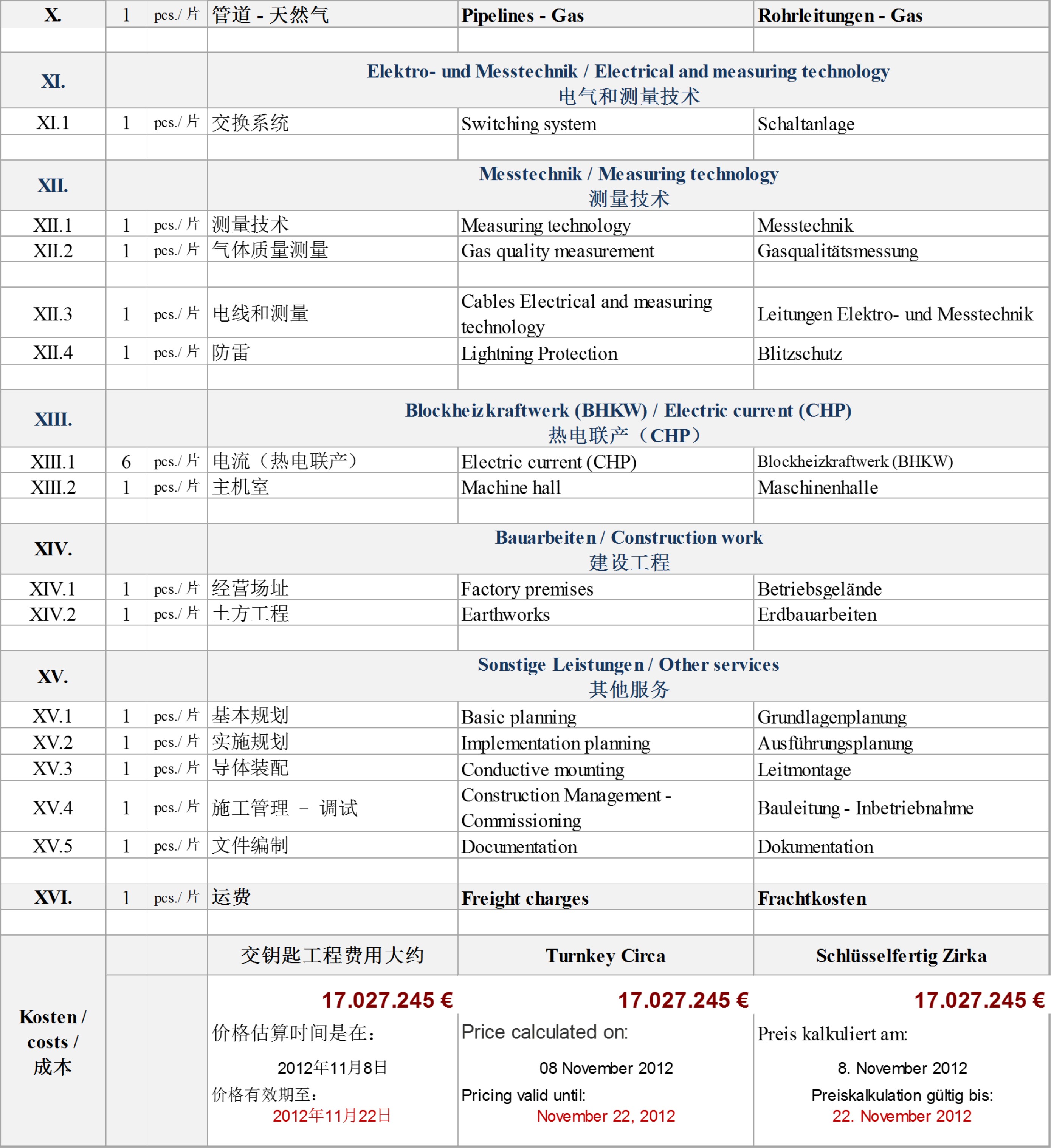

| | | B.1. FOR AGRICULTURAL APPLICATIONS The provision of energy for the supply of an efficient society can be ensured in remarkable proportions with natural resources of a modern agriculture. Biogas plants can produce high-quality energy (“biogas”) out of agricultural and other bio-residues like e.g. liquid manure from the keeping of cattle, and so on. Afterwards the biogas is refined in fully developed gas engines to electricity and heat. | B.1. 農業應用 一個有效的社会提供的能源供应能够确保现代农业自然资源的显著比例. 沼氣發電廠可從農業殘餘物和生物垃圾,如从饲养豬, 牛和家禽得来的液体粪便等, 生产出高品質的能源 (沼氣) 。此后, 沼气被提纯,可燃烧的气体经过全面改进的燃气发动机产生电力和热。 | B.2. BIOGAS PRODUCTION The technique of the biogas production is known for decades and all over the world small and large biogas plants are operated successfully. The heart of a biogas plant is the digester, in which the methane bacteria use e.g. liquid manure from the keeping of cattle and dried straw powder as “food” to produce biogas out of it. Biogas consists of approximately 50 – 65 % flammable methane. The methane provides the required energy for the gas engine so that the engine can power a generator, which produces electricity as a good sellable product. According to the german “Renewable Energy Law” an attractive remuneration for electricity from renewable resources/ energy plants is paid. Therewith a high profitability of the biogas plant and the agricultural enterprise can be ensured. Beside the digester and the combined heat and power unit (CHP) a biogas plant has a few more components such as a substratum receiving station, pumps, gas treatment, gasholder and a storage tank for the fermentation product. | B.2. 沼氣生產 沼氣的生產技術已經被人知晓有幾十年的时间. 在世界各地的小型和大型沼气工厂都在成功运行. 沼气厂的核心是消化罐. 在消化罐中,甲烷菌以发酵基质如混合的粪便和干秸秆粉等为 “食物” 生产出沼气。 沼氣中含有約50 - 65 %的可燃燒甲烷气。甲烷气提供气体发电机所需要的能源來發电. 以便发电机产生電力. 電力是一個很好出售的“產品”. 根據“可再生能源法”用於生產的電力如果來自可再生原材料,会得到有吸引力的報酬。. 对此,沼气工厂和农业企业可以得到高利润的保证。 除了沼气池和热电联产机组(热电联产)一个沼气厂有一些更多的组件,如底层接收站,泵,氣體處理,氣體存儲器和和发酵生产原料的储罐。 | B.3. FERMENTATION RESIDUE AS FERTILISER The fermentation residue plays an important part in the operating of a biogas plant which runs on liquid manure from the keeping of cattle / power plants. Inside the digester only the carbon is extracted from the renewable resources. The carbon is contained in the biogas as methane and carbon dioxide, which were metabolized by the methane bacteria. The rest of the nutrients are still contained in the fermentation residue. The nitrogen is available as the attractive ammonium. | B.3. 发酵残余物作為肥料 发酵残渣在一个使用可再生资源的沼气发电厂的运作中发挥着重要的作用. 沼气池内, 只有碳被从可再生资源中去除。 沼气中含有碳.甲烷和二氧化碳.它们由甲烷菌新陈代谢产生. 其余的养分仍然存在于发酵残渣中。氮可作为有吸引力的铵得到。 | B.4. HEAT AND COLD UTILISATION Beside the electrical power also heat is produced. This heat can be used for the heating of buildings and glasshouses, drying of several goods, for fish farming and many more purposes to increase the efficiency of the biogas plant. The intelligent utilisation of the produced heat is remunerated by the legislator with an additional bonus. The heat can also be converted to cold. With this cold you can operate cold stores, or use in the summer as air conditioning. | B.4. 冷熱能源的利用 除了電力,熱能也被生产。這種熱能可用於建築物的供暖和溫室. 可用于各種貨物的干燥,用于鱼类养殖和有更多的用途,以增加沼气厂的經濟效益。 熱能的智能利用可向立法機關獲得額外的獎金。 熱也可以被轉化為冷。您可以把它用于冷藏庫,或用于 夏天的空調。 | B.5. PROCESS DESCRIPTION The biogas process is based upon the activity of so called methane bacteria. These bacteria “eat” organic substances which are available from the manure or the energy plants (renewable resources). A small part of the “food” is needed for the growth of the bacteria, but the largest part of these substances is excreted as gas. The principal constituents of the biogas are flammable methane and not flammable carbon dioxide. Substantial amounts of methane are produced which can be transformed with gas engines into electricity and heat. The biogas plant consists of several components so that biogas can be produced out of the organic substances: In the first instance the substances out of which the biogas is produced, such as e.g. liquid manure, is stored in a receipt station. If required in this container fermentable substances, such as e.g. fats, can be added as co-substratum. The sludge is pumped constantly from the container in the digester. The digester is a completely closed tank made of steel or reinforced concrete. The digested sludge in the digester has a temperature of approximately 35°C. This high temperature provides optimal living conditions for the methane bacteria, so that an effective gas production can result. The digester is equipped with heat insulation to keep the self energy consumption low. Furthermore the digester is constructed gas-proof because the bacteria only survive and work under the absolute elimination of oxygen. The produced gas is discharged in a pipeline. In a purifying unit condensate and contaminants are eliminated. Afterwards the gas is stored intermediately in a gas holder and from there is transformed by a combined heat and power unit (CHP) into electricity and heat. The electricity can be used internally or fed gainfully in the public electricity network. The heat is used partly for the heating system of the digester. The surplus of the heat quantity from the CHP can be used for e.g. keeping of pigs, glass houses, drying processes, etc.. The biogas process proceeds continuously, that means every day sludge is pumped into and a corresponding amount is taken out of the digester. The digested sludge is stored in a storage tank till it is used as fertiliser for the arable land. The pre- and the final storage are installed beside the digester. Tthe pump technology, gas treatment and the CHP are installed on strip foundations in factory-made pre-assembled containers. | B.5. 程序描述 沼氣的产生過程是基於所謂的甲烷菌的活動。這些細菌“吃”掉粪便和能源植物中的有機物質. 存在。甲烷細菌的生長需要吃掉一小部分“飼料”,大部分這些物質將作为氣體被排出. 沼气的主要成分是易燃的甲烷和不易燃的二氧化碳。所生产的大量的甲烷可被燃气发动机转化成电和热。 沼气工厂包括若干组成部分,这样就可以用有机物质产生出沼气.首先,用于生产沼气的物质,如液体粪便被存储在一个接收站。如果该容器内的发酵基质需要,比如脂肪,可以增加为共同底层基质。 沼渣被不断从发酵罐中泵出。发酵罐是一个完全封闭的用钢筋混凝土作成的罐 在发酵罐中约35 度的温度中发酵原料被消化。這種高溫为甲烷菌提供了最佳的生存條件,因此,可以有效产生沼氣。 厌氧发酵罐配備了熱絕緣设备以减少自身能量的消耗。另外,发酵罐还建造有气体密封装置,因为,細菌只在完全厌氧的环境下工作。 产生的沼气從发酵罐的管道被排放出。在提纯装置里,凝析油和污染物被消除。然後可燃气体暫時被儲存在一个气体储罐中,並從那裡被输送到一个熱電聯產装置以生產電力和熱。電流可用於内部使用或溃入公共電網。或把可燃气体直接输入天燃气管道和做车用燃气。 从熱電聯產装置得来的部分熱被用來加熱发酵罐( 保持发酵罐内的恒温)。多餘的熱量可被用于养殖场建筑内部的供暖或致冷,供应温室和乾燥工藝等。 沼氣产生的过程是連續的。即每天泵入原料并從发酵罐中泵出相应數量的沼渣。发酵过的原料经固液分离后被储存在储罐中,并被加工成液体肥料和固体废料用于有机农业。在发酵罐旁邊安装有前期和后期的存储设备。 泵技術站,气体处理和在工廠被預組裝的熱電聯產发电机组集装箱安装在条形地基地里。 | B.6. CONSTRUCTION OF A BIOGAS PLANT A biogas plant is a small factory, the various appliances, containers and equipment such as pumps and motors, in order to produce biogas and electricity to be able to convert. The components need to be sensible voted for an effective and trouble-free operation can achieve. The main components of a biogas plant are described below for an idea of building a biogas plant to receive. | B.6. 一個沼氣工廠的建設 沼氣廠是一家小工廠,有各種設施,容器和设备,如水泵,電動機,以便產生沼氣并轉化為電能。各組成部分需要切合实际的协调一致产生一個有效和無故障操作才能實現。 收到建立一個沼氣廠的想法后。沼氣工廠的主要組成部分分述如下, | B.7. FERMENTER The fermenter, or septic tanks, is the most important part of a biogas plant. In fermenter, the liquid manure from the keeping of cattle converted into biogas. The fermenter consists of a large gas-tight containers, made of reinforced concrete or steel is. We can, depending on the desired and necessary requirements Fermenter both systems (s u) offer. | B.7. 發酵罐 發酵罐,或者被称为“厌氧消化罐”,是沼氣廠最重要的一個組成部分。在發酵罐中,液体的粪便等有机垃圾轉化為沼氣。 發酵罐包括一個大的由鋼筋混凝土或鋼材製造的不透氣(密封)的容器。 我們可以根據所期望的和必要的要求,提供两种發酵系统的发酵罐(見下文)。 | B.8. CONSTRUCTION OF FERMENTER The fermenter is a stationary cylinder with a ratio of diameter to the height of approximately 1:1 and is made with a special shuttering on the spot. The slim reinforced concrete container can be executed into heights of 8 to 20 m. Is established either from reinforced concrete or from stainless steel plates the ceiling or roof structure of the container and closes gastightly. The roof is usable so that in the maintenance or repair case all important safety and machine technical equipments of the fermenter can be reached. | B.8. 發酵罐的結構 發酵罐是一個高度和直徑的比率約為1:1的固定气罐。 由特殊的模板制造。 轻质的鋼筋混凝土的容器可用於8至20米的高度。 它是用鋼筋混凝土或不銹鋼板建造。容器的天花板或頂盖结构是不透氣和封閉的。 頂盖可以在維護或修理的情况下使用。可以检查所有發酵罐的重要的安全设施和機械設備。 | Fermenter with vertical stirring work | 發酵罐 / 垂直攪拌器 |

|

| Example / 典范

| The safety and machine technical equipments of the container are essentially in the gas cathedral which is installed in the roof structure. The withdrawal of the biogas takes place in addition over this gas cathedral from the fermenter. Optional two different radical change systems provide a sufficient radical change and by mixture of the container contents. The first system is the radical change with a vertical stirring work which is installed over the gas cathedral in the roof structure. The concrete used for our reinforced concrete containers is a high-quality special concrete which is constant against attacks by a variety of aggressive media. A special PE-high-density coating which effectively protects the concrete from sulphur corrosion is in addition attached in the gas room of the bad container. On the outside the fermenter is thermally insulated and with trapezoidal sheet covered with mineral wool. Work platform and ladders are in the extent of supply. Connections for the supplying and eduction of the mud and the gas are included like the vertical stirring work for an effective by mixture. The warming of the mud is carried out via a double tube heat exchanger lying on the outside. | 容器的安全和機械設備主要分佈在安裝在頂部结构的气室里。 对沼气的額外抽取发生在沼氣罐气室的上方。 可选择两种不同的基础交换系统通过容器内物质的混合提供充足的基础交换。 第一個系統是一個带有垂直搅拌作用的基础交换。它被安装在位于屋顶结构的气室的上方。 用于建造鋼筋混凝土容器的混凝土是一种高质量的特種混凝土。它可以长期抵抗各種腐蝕性介質的攻擊。 此外,一種可有效保护硫对混凝土腐蝕的特殊的高密度聚乙烯塗層被附着在消化罐的气室里。 發酵罐的外部由石棉複盖的梯形薄板隔熱。 工作平台和梯子是在可提供的范围内。 供应和发酵基质的培养, 以及包括气体在内的通过垂直搅拌操作的有效混合的連接。 基质的升溫通过雙管式換熱器进行。 |

| B.9. SLIM STYLE In comparison with fermenters in a flat style bad containers stand out due to the following advantages in a slim style:

Roof structure By the relatively small diameter of the containers stable roofs have to be established easily. Stirring appliances working effectively can be integrated in stable roofs. Heat losses can want to a good insulation be made minimised also in the roof there. With a good insulation the warmth of one's own need of the bad container is minimised so that the warmth can be used economically and increases the yield of the biogas plant. In comparison with thin membrane roofings the heat losses are up to 75% lower. The slim style is the prerequisite for an optimal homogenization of the bad container contents. The relationship height: Diameter = 1:1 is advisable for a good by mixture of the contents. The surface is smally, through this be able to sink and swim stack be fought better. A good distribution of the warmth and the fresh fermenting good is obtained with that with a low expenditure of energy, this is an essential prerequisite for an optimal bio gas-production. This can be much more simply and more safely to operate reached unlike fermenters in a flat style. At a disturbance the stirring appliance can be dismantled without the one emptying of the fermenter becomes necessary. | B.9. 小型建筑风格 相比發酵罐的平板的建设特點,消化罐的輕薄設計由于以下優點脱颖而出: 頂部结构 由於相對較小直徑的容器穩定的頂部结构更容易建造,。搅拌设备的工作可以有效地在稳定的顶部结构内进行。 在那样一个很好的保溫隔熱的頂部结构内,熱損失可以減少到最低限度。 具有良好的隔热的消化罐,减少了其自身需要的热量,热能会被经济地使用,并增加了沼气厂的热能产量。 相對於哪些用橡胶薄膜做的頂部结构,我们钢筋混凝土的顶部结构将发酵罐熱量的損失降低了75 %。 轻薄风格設計的先決條件是发酵罐的物质有一個最佳的同質化。 相关的高度:直徑= 1:1 有利於有一個良好的物质的混合。 由于表面小,物质可以更好的下沉,漂浮的堆积物质被更好地粉碎。 一個好的熱量分配和使用低的能源消費获得新鮮發酵物质。 這是一個最優沼氣生產必不可少的先決條件。 不同于平板式的发酵罐,這种消化罐的操作更简单和更安全。 在發生故障时,該攪拌器可被去除,不需要清空發酵罐。 | B.10. SUBSTRATUM SUPPLYING The substrata made of which the biogas can be won are very various. A biogas plant can be operated with liquid substrata like dung, dried straw powder, sewage, sludge, and other bio-wastes. An adapted supplying technology is therefore an indispensable necessity for a trouble-free operation. The supplying and preparation of the substratum takes care that the substances are brought in liquidly into the Bio gas fermenter to obtain an effective operation. | B.10. 基质供应 产生沼氣的基质有多种物质 一个沼氣厂可使用养殖场的液體粪便,屠宰场和食品加工厂废水,污水处理厂的污泥,或其它生物质废弃物,农林废弃物来运作。 要做到无故障操作。先进和与发酵原料适应的技术是不可缺少的和必要的. 基质的供應和准备要確保液体物质被送入沼氣发酵罐,以保证有效的運作。 | B.11. FERMENTING SUBSTRATUM RESIDUE The mud which leaves the Biogasfermenter is still a valuable substance. Only the carbon has been withdrawn from the liquid manure from the keeping of cattle for the biogas extraction. Furthermore nitrogen, phosphorus and the further plant nutrients are available and n can be used optimally for the manuring in the agriculture. The fermenting remains are therefore stored in a store bin which can take a stock of 180 days. Particularly the nitrogen is in the ground wholesome ammonium form and can be used effectively in the growing season. | B.11. 发酵基质残渣 从沼氣池中排出的发酵残渣仍然是一种寶貴的物质。在沼氣提取中,碳是唯一被去除的。氮,磷和其他植物的營養物質仍然存在于残渣中,可在农业上作为生态( 绿色和无公害)有机肥料被最大限度地利用。 發酵残渣可以在存儲容器中儲存180天。 特別是氮是在地面以銨的形式得到。可有效地用于种植季节的施肥。 |

|

|

|

|

| |

| |

|

| | B.12. GAS CLEANING The biogas which leaves the fermenter still must be processed for the use in the gas engine, so that the engine has a long life time. Condensate (water) must essentially be removed from the gas. As well the hydrogen sulphide which is contained in different concentrations in the biogas must be removed. Hydrogen sulphide is poisonous and very corrosive. The HÖBA corporate group has extensive experiences and techniques for the effective elimination of pollutants of gas. A pressureless gas carrier serves the even supply for the block-type thermal power station to guarantee an uninterruptable operation. A need torch rounds off the gas cleaning and provides an environmentally favourable and sure disposal of the gas in the disturbance case. | B.12. 沼气净化 离开发酵罐的沼氣依然需要进行加工后才能被用于气体发动机。 以便发动机能有长时间的工作寿命。 凝结水必须全部地从沼气中去除。 同樣,不同浓度的沼气中含有的硫化氢也必须清除。 硫化氫是有毒的和有非常强的腐蝕性。 对有效地清除沼气中的污染物,赫巴集團公司有著豐富的經驗和技術。 一个没有压力的气体运输罐为热电联产发电站提供供应服务以確保设备不間斷運行。 需要有一个点火器来圆满结束气体的清洁,并提供一个良好的环境和保证在有故障的情况下气体的安全处置 | B.13. COMMUNAL HEATING/POWER STATION The block heating work changes the biogas in electric current and warmth, two energy forms are valuable secondary energies which gain large proceeds and make the biogas plant profitable that way. Block-type thermal power stations can be delivered in all sensible sizes. For the fast assembly the block-type thermal power stations can prefabricatedly be delivered into containers. An assembly in buildings is also possible. The current from the block-type thermal power station is escorted and tempered correspondingly about a transformer station after the conditions of the energy-feeding in law into the public power supply system. The warmth can be used variously e.g. to the heating of buildings and hothouses in the fish farm or too technical processes like the drying of wood or other goods. | B.13. 热电联产发電站 该热电联产发电站把气体转化为电流和热能。 该兩種形式的能源是寶貴的二次能源。并可以获得大的收益,使沼气厂盈利。 可提供有各種合理規格的熱電聯產发电站。熱電聯產发电站可被快速预先装配在集裝箱内交付。 安裝在建築物内也是可能的。从熱電聯產发电站产生的電流將由一個變電站根據法律规定的电能溃入条款进入公共電力網。 熱能可以用於不同的项目,例如建築物内的供熱和溫室,养鱼场 或干化技術過程, 如乾燥木材或其他物品。 |

|

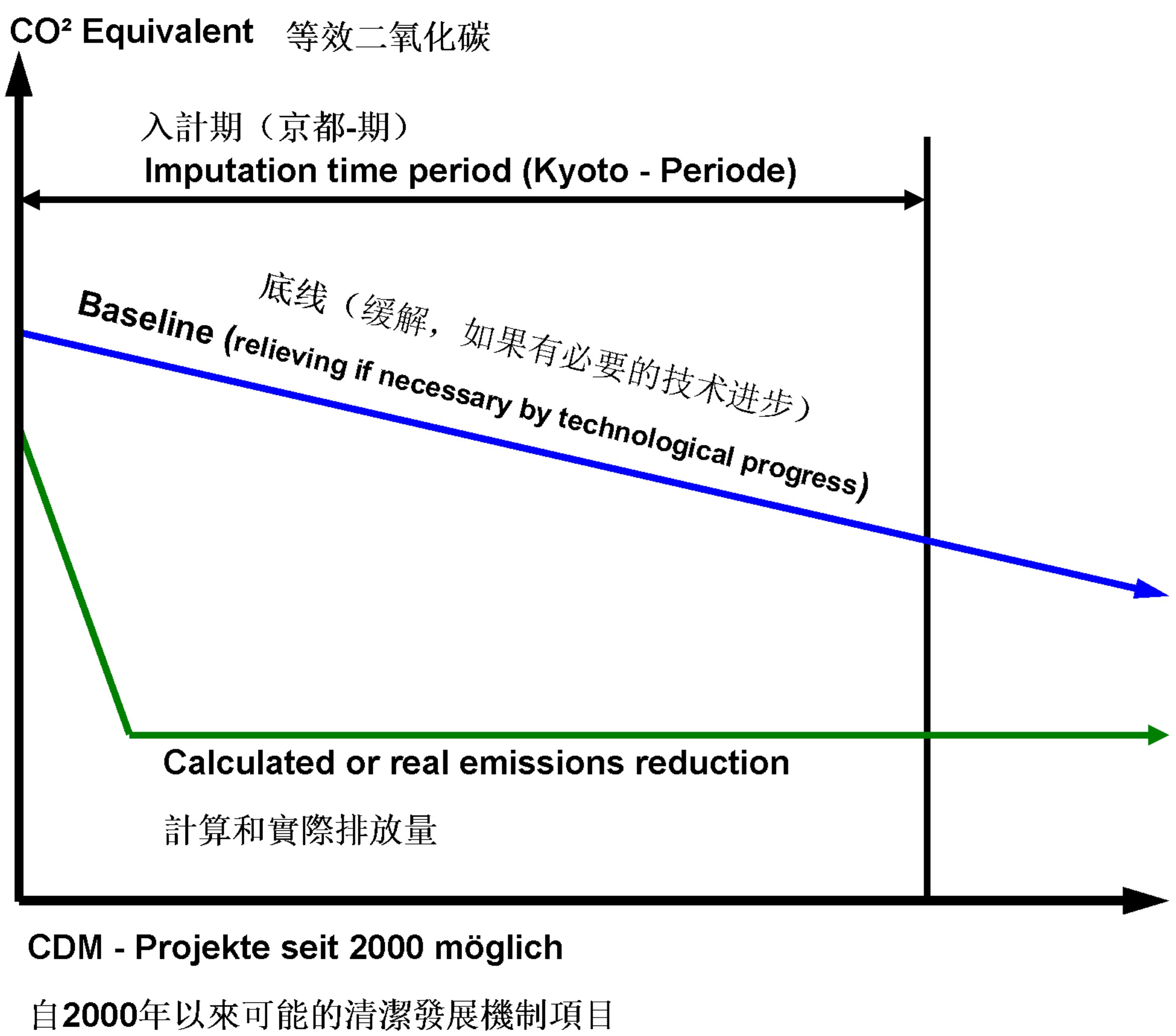

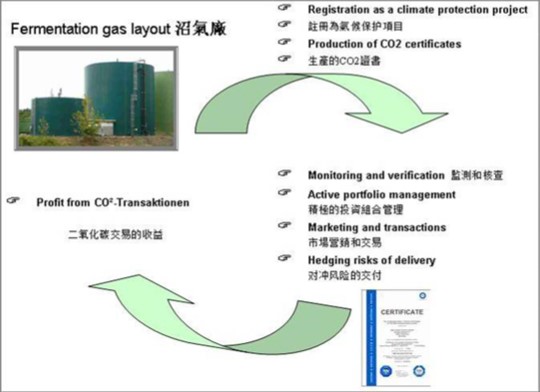

| | | C. CLIMATE PROTECTION PROJECTS | C. 氣候保護項目 | Climate protection projects can with | 氣候變化項目 | C.1. CLEAN DEVELOPMENT MECHANISM (CDM) | C.1. 清潔發展機制( CDM ) (環境友好機制的發展) | being carried out. | 執行 | | | With the CDM under the Kyoto Protocol committed governments and companies generate mitigation credits. These are investments in saving projects in developing or emerging countries. The mitigation credits | 京都議定書下的清潔發展機制要求各國政府和企業提供信貸。 這些是投資在發展中國家或新興國家的節能减排工程。 | C.2. CERTIFIED EMISSIONS REDUCTION – CER | C.2. 经核證的排減量 CER | these by these projects arise, can be credited to the investor since 2005. These credit notes are tradable. | 通过这些项目所产生的( CER),可记入自2005年以来投资者的名下。这些(CER)是可以在国际上进行交易的碳减排指标。 | Carbon dioxide contributes considerably to the warming of the atmosphere - CO ² as a waste product of combustion of fossil energy carriers like carbon, mineral oil, natural gas. | 二氧化碳-甲烷气作为化石能源载体比如碳,矿物油,天然气燃烧的废弃产品。大大促进了气候变暖, | This has serious effects on the environment and the social structure. Methane - CH4 - arises in large quantities at the rice growing and in the cattle keeping. | 這已嚴重影響了環境和社會結構。 甲烷-CH4, 甲烷-來自大量的水稻種植和牲畜养殖业。 | At the unchecked storage of dung large quantities of methane are handed in into the atmosphere. At methane, the harmfulness for the atmosphere is greater than at carbon dioxide around the factor 21! | 如果不加控制地儲存糞便,大量的甲烷会進入大氣。甲烷对大气的危害比二氧化碳的危害大21倍 | | | C.3. PROJECT TYPES - EXAMPLES | C.3. 項目類型-實例 | Energy efficiency project - co. ² | 能源效率項目-二氧化碳 | Rise of the degrees of effectiveness from power stations cogeneration of power and heat | 提高熱電聯產电力和热的效率, | Renewable energy - co. ² | 可再生能源-二氧化碳 | Biomass - particularly procedure to the methane avoidance | 生物质-避免甲烷的特别程序 | Methane avoidance - CH4 | 避免甲烷 | Landfill gas, gas from purification plants | 垃圾填埋氣,污水净化厂氣體 | Minegas | 煤层氣 | Manure slurry management - Cattle ranching | 牲畜糞便管理 | C.4. CRITERIA OF SUSTAINABLE DEVELOPMENT - SUSTAINABILITY - | C.4. 可持續發展的標準: | After the Kyoto Protocol a sustainable development can be described with the following criteria: | 根據京都議定書,可持續發展的標準描述如下: | | | Economy: Creation of prosperity and livelihoods concrete generation of incomes job creation. | 經濟學: 創造財富和實際生活收入,創造就業機會 | Sozial: Improvement on the quality of life, abolition of poverty concrete development of the water supply, sewage system energy supply. | 社會: 提高生活質量,消除貧困,特別是發展供水,污水处理系统能源供应 | Ecology: Improvement, increase and expansion of the natural resources concrete reduction of use of fossil energy Improvement of the air quality Improvement of the land utilization | 生態學: 改進,加強和擴大自然資源,具体的减少使用化石能源 改善空氣質量 改進土地利用 | | |

| |  | | | C.5. BASELINE | C.5. 基線 | The baseline serves and to find the consequence of a project out. A scenario is built in the front-end and to grasp the situation without execution of the project. | 使用的基线影響到找出一個項目的结果,在前端酝酿建立一个设想并在把握形势下执行项目。 | It is tried also to include the technological progress and changes of the legal framework conditions. | 它同時也试图包括了技術進步和法律框架条件的变化。 |

| | | C.6. COURSE OF THE PROJECT | C.6. 項目课程 | Working steps | Responsibly | 步驟 | 責任 |

|  | Project Idea Note PIN | Project design Document PDD | 項目概念書 | 項目設計文件 PDD | In the Project Idea mark the project bearer states general information about the project. The PIN serves for the preliminary examination of the project. | The successful registration of a CDM project assumes the production of a comprehensive project documentation – PDD. She is comparable with a licence application and puts high requirements for the proof of the additionality (Additionality). | 在項目理念里面,承载着国家有关项目的一般资料。项目概念书适用于项目的初步审查。 PIN是用於篩選項目。 | 成功註冊的清潔發展機制項目,假定建立一個全面的項目文件-PDD。它是類似于申請許可證,並提出很高的要求證明額外性。 | | | C.7. REALISATION | C.7. 实现 | After registration of the project as a climate protection project and the necessary formal liquidation by a specified service company the condition is created created for the generation of the certificates. The certificates have a tradable value and serve the Refinanzierung of the layout. | 注册後的項目作為一個氣候保護項目,需要由專門的服務公司正式的處理,創造生成證書的條件。該證書有交易的價值和融資服務的布局。 | C.8. ECONOMIC EFFICIENCY | C.8. 经济效率 | The climate protection projects should show a least size. The formal liquidation is cost-intensive, so that bigger projects or "convoy projects" can lower these expenses. | 气候保护项目至少应该表明规模大小。 正式解決成本昂貴,因此,較大的項目或“車隊項目”可以減少這些費用。 |

|  | | | E. FUNCTION GRAPH EXAMPLE | E. 功能图示 |

|  |  | | |  | | | | | If we have all the documentation that we need for a serious pre-planning, we can of course call binding numbers and handle also the sludge from your sewage treatment plant in fermenter and convert the energy contained in electricity. | 如果我们能得到所有我们需要的的文件和资料来做出认真的初步设计,我们当然可以计算出确切数据,以及把你们污水处理厂的污水污泥泵入厌氧发酵罐一并进行处理,把其中所包含的能量转化为电能。 | | | To hear from you soon a positive response, we remain | 我们殷切希望很快得到你们积极的回应。 | Sincerely yours |

| Johann Hoereth 赫列·约翰 President of 公司东主/总裁 hoeba j. hoereth gmbh 赫巴 约翰。赫列有限公司 | | | | | Creator: | 承包者和創建者: |

| Regie /直接经管人: Johann Höreth /赫列·约翰 Planning /規劃: Helmut Muche / Chief Engineer, Architect / 水利工程的总工程师 建筑师和专家 Specialist for Process Engineering and Hydraulics | | |

|

|

|

|

|